IC & Compound Semi Manufacturing

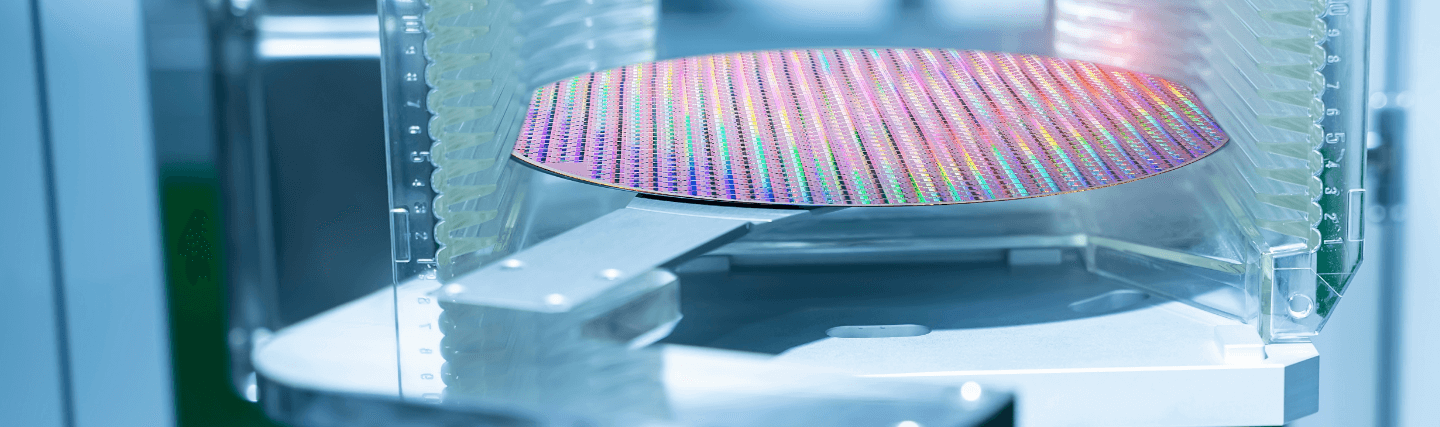

Discover How We Support IC and Compound Semiconductor Manufacturing

There aren’t significant differences in the tools used to manufacture silicon integrated circuits (ICs) and compound semiconductors (also known as III-V materials). But the process recipes can be significantly different due to the characteristics of the substrate materials. At ACM Research, we develop unique wafer processes that address challenges in both IC manufacturing and compound semiconductor manufacturing.

Do You Have Varied Needs for Your IC and Compound Semiconductor Processes?

When you partner with us, you’ll tap into the most advanced semiconductor processing systems available for a host of single or batch wafer processes including cleans, etch, strip, and metal lift-off, as well as electroplating, stress-free polishing, and thermal processes. Our tools are customized to meet your needs, from current and future technology nodes to advanced compound semiconductor applications.

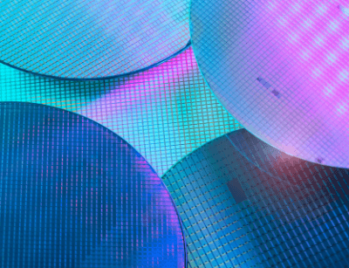

IC Manufacturing

As logic and memory device technology nodes continue to shrink, we continually innovate wet wafer process solutions that address both your legacy and advanced technology requirements.

From the tiniest particles to the most stubborn residue, our systems are designed to eliminate and prevent potential causes of defects from any wafer surface, regardless of topography.

Compound Semiconductors

The future of e-mobility and advanced communications demands power devices based on compound semiconductors. Did you know that some of the same tools used in manufacturing silicon-based ICs can be used in compound semiconductor wafer and device manufacturing? We’ve adapted our wet process equipment line to suit the needs of specialty materials like Silicon Carbide (SiC) and GaN.

Contact Us

We look forward to providing customized solutions for your wet wafer processing, ECP, Furnace, Track, PECVD, and SFP applications.