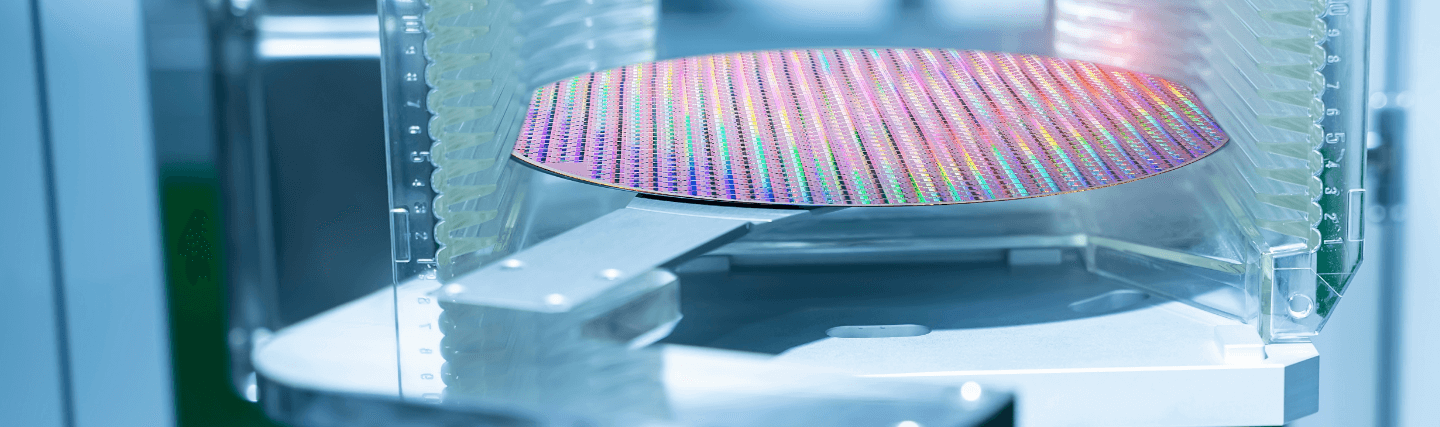

Semiconductor Manufacturing

Discover How We Support IC Manufacturing

To accommodate the requirements of digital devices, you’re developing progressively faster, more powerful, smaller, and lower-cost semiconductors chips. You need process tools that help you achieve the finest feature geometries while also preventing the “killer defects” that reduce yields and, therefore, profit. At ACM Research, we’ve got the tools to support you.

Proprietary Cleaning and Deposition Processes

As logic and memory device technology nodes continue to shrink, we continually innovate proprietary solutions to address both your legacy and advanced technology requirements.

- Smart Megasonix™ combines jet spray with transient cavitation to gently remove stubborn particles from fragile IC circuitry

- Space Alternated Phase Shift (SAPS™) technology uses megasonic waves to remove random defects from flat and patterned wafers

- Timely Energized Bubble Oscillation (TEBO™) provides efficient, damage-free cleaning for both conventional 2D and 3D patterned wafers at advanced process nodes

- The Multi-Anode Partial Plating function in our ECP systems successfully deposits metal layers on dual damascene structures or through silicon vias

- Our Ultra Furnace platform addresses dry processing challenges of low-pressure chemical vapor deposition (LPCVD), atomic layer deposition (ALD), oxidation, and annealing

The bottom line: Our systems remove the tiniest particles and most stubborn residue and deposit ultra-thin, full-coverage films. They are designed to eliminate and prevent potential causes of defects from any wafer surface, regardless of topography.

Cleaning Systems—Ultra C SAPS

Learn More

Cleaning Systems—Ultra C TEBO

Learn More

Cleaning Systems—Ultra C Tahoe

Learn More

Cleaning Systems—Single Hot SPM

Learn More

Cleaning Systems—Bevel ETCH

Learn More

Cleaning Systems—Ultra C b

Learn More

Scrubber Systems—Ultra C s

Learn More

Cleaning Systems—Ultra C wb

Learn More

Plating System — Ultra ECP map

Learn More

Plating System—Ultra ECP 3d

Learn More

Furnace Systems—Ultra Fn

Learn More

Furnace Systems—Ultra FnA

Learn More

Furnace Systems—Ultra FN Atmospheric Pressure Oxidation/Anneal

Learn More

PECVD Systems—Ultra Pmax™

Learn More

Track Systems—Ultra Lith Track

Learn More

Contact Us

We look forward to providing customized solutions for your wet wafer processing, ECP, Furnace, Track, PECVD, and SFP applications.