Stress-free Polishing

Discover ACM’s Stress-free Polishing Capabilities

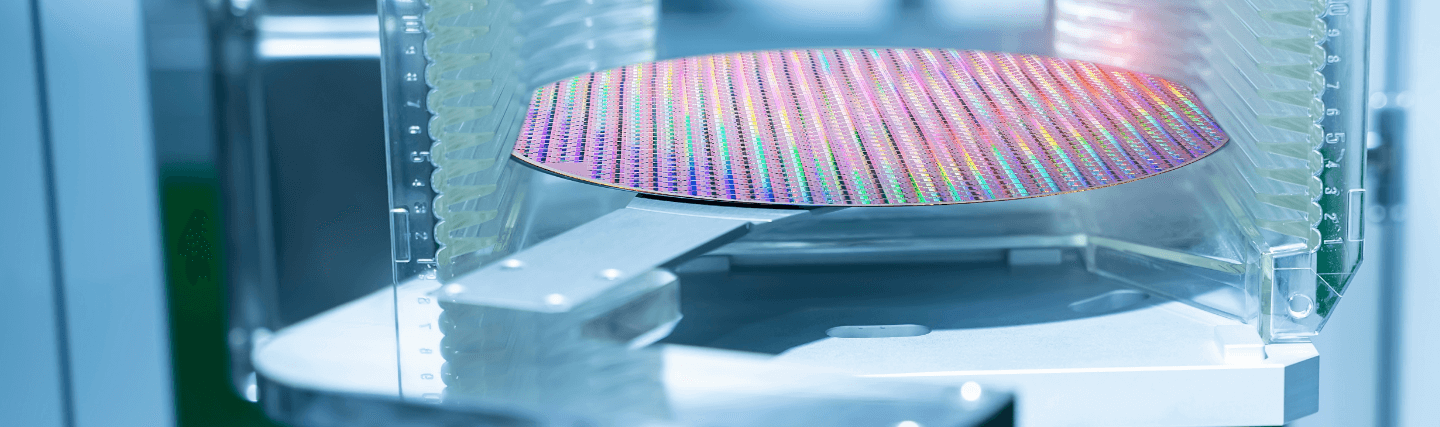

If you’re keeping pace to support the heterogeneous integration roadmap, you’re continuously innovating your advanced wafer-level packaging processes to keep pace with tightening TSV aspect ratios and tightening redistribution layer (RDL) line/space requirements. If your yields are suffering due to planarization challenges like Cu overburden for TSV fill or wafer warpage, our stress-free polishing systems for advanced packaging applications may be the key.

Stress-free Polishing Improves Your CMP Yields

Chemical mechanical planarization (CMP) alone is no longer enough to address your yield issues associated with TSV and fan-out wafer-level packaging (FOWLP) processes. Additionally, CMP comes with sustainability challenges because of chemical usage and disposal. Toxicity levels and decomposition issues associated with CMP process chemistries make their disposal difficult.

That’s why we developed our proprietary stress-free polishing (SFP) technology. As the perfect complement to CMP, SFP electrically removes metal ions from the wafer surface. It’s also environmentally friendly thanks to its built-in recycling system. Electrolyte and wet-etchant chemistries are recycled through the system and reused in real time to significantly reduce the overall usage of chemicals and consumables.

Stress Free Polishing Systems—Ultra SFP

Learn More

Contact Us

We look forward to providing customized solutions for your SFP applications.