Cleaning Systems—Metal Lift Off

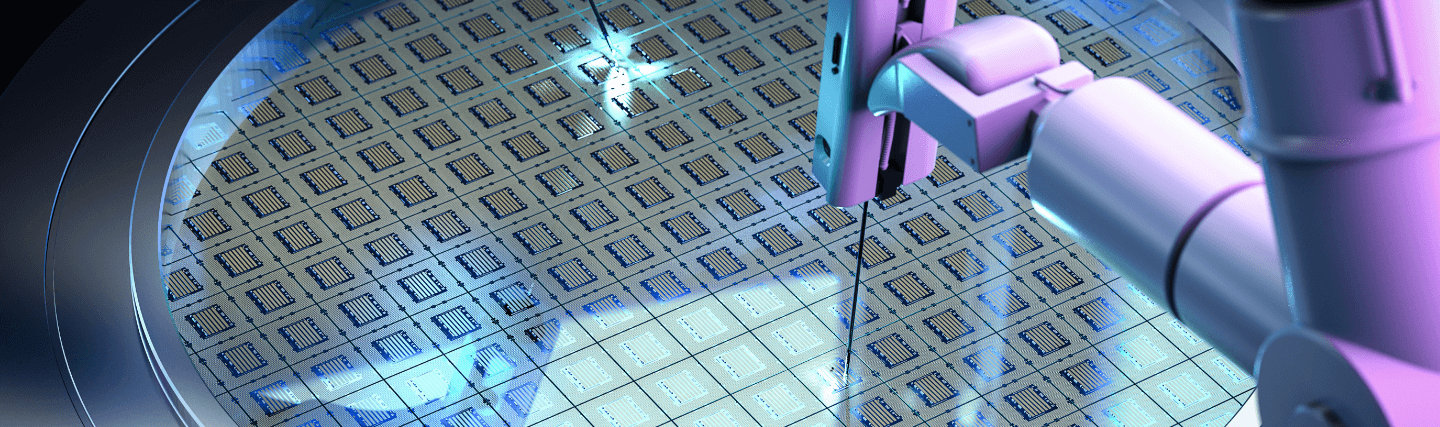

Discover ACM’s Metal Lift-off Capabilities

If you’re still using photolithography followed by etch processes to create structures for your power semiconductors or interconnect patterns for FOWLP applications, you may be seeing undesirable effects on the delicate layers below. You may also be looking for a more cost-effective approach to replace traditional etch steps. We can help.

Metal Lift-off Saves Time and Money

Metal lift-off (MLO) may be the process solution you’ve been looking for. As an alternative to photolithography and etch processes, it eliminates an etch process step, reducing cost, optimizing cycle times, and sharply reducing chemical demand at high temperatures.

We know you may have concerns about metal retention, formation of sidewall “ears,” or the redeposition of metal particles. We’re addressing the complexities of MLO through a unique combination of wet bench and single-wafer manufacturing technology to deliver high throughput and superior removal performance. A dual-filter system ensures optimal cleanliness during manufacturing. In addition, our Smart Megasonix™ systems provide just the right combination of wet deposition and removal processes to lift the metal off the photoresist, leaving just enough to pattern the wafer.

Contact Us

Looking for spare parts and customer support for your ACM Research Systems?